Description

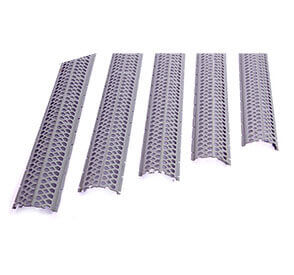

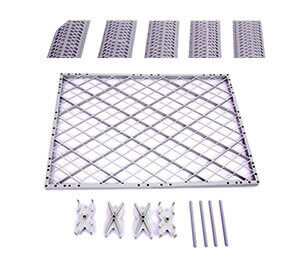

Perforated V-Bar is the most extensively used product in the industry. Technopick Polyplast can supply the stainless steel or FRP coated wire mesh as well as the other components that are needed for the entire splash bar system.

The water droplets spread over the solid surface and perforated holes of the splash bar. The flowing water is held on the holes due to surface tension and forms a thin film. The water film formed over these rectangular holes has very low surface tension at its corners and thus a tendency to rupture frequently. During this process of rupturing the water film is broken into small globules, thus providing maximum heat transfer.

Features and Advantages

- Diamond shaped perforations are recommended as they offer the ideal surface tension to rupture the water droplets.

- The top edge of the V-bar is reinforced so as it offer bending and load strength..

- Ensuring a minimum thickness of 1.5mm and a maximum distance of 600mm between adjacent bars will help reduce the possibilities of sagging.

- Compact locking of the V-Bar on the grid using a V-Bar clip (as depicted in the picture) will also ensure a sturdy fill structure.

- The overhang of the V-bar of the last grid should be restricted to 150mm.

- Algae resistant and Fire retardant

Technical Specifications

| Characteristics | Perforated V-bar |

|---|---|

| Material of Construction | Rigid PVC |

| Overall Dimensions | 62mm x 62mm |

| Length | Length |

| Shape and Size of Perforations | Diamond / Circular |

| Thickness at load points | 1.2mm to 1.5mm |

| Colour | Black / Grey |