Description

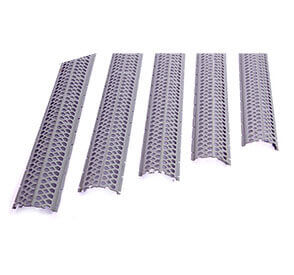

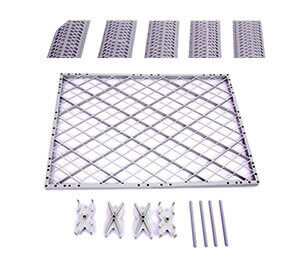

The rectangular timber slats provide very little in terms of enhanced surface area for the air and water to mix. Technopick Polyplast has designed perforated slats to replace existing rectangular timber slats with upto 20% increase in efficiency.

The water droplets spread over the solid surface and perforated holes of the splash bar. The flowing water is held on the holes due to surface tension and forms a thin film. The water film formed over these rectangular holes has very low surface tension at its corners and thus a tendency to rupture frequently. During this process of rupturing the water film is broken into small globules, thus providing maximum heat transfer.

Features and Advantages

- Better heat transfer ratios due to the formation and quick rupture of water film on diamond shaped perforations.

- Pack volume is reduced to 10% to that of timber slats.

- Increases the void volume in the tower, resulting in higher capacity.

- Economical and durable compared to wooden slats.

- No channeling of water.

- Perforations provide a considerable reduction in pressure drop resulting in lower power consumption and/or increase in air flow

Technical Specifications

| Characteristics | OPTI GRID Splash Grid |

|---|---|

| Material of Construction | Perforated Slats (C-Bars) |

| Overall Dimensions | 38 mm x 13 mm |

| Length | Any |

| Shape and Size of Perforations | Pentagon |

| Thickness at load points | 1.0 mm +/- 0.1mm |

| Colour | Black / Grey |