Description

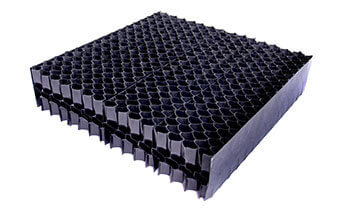

The eliminators can be supported at spans as high as 1800mm. Made out of UV resistant UPVC confirming to standards set by CTI-STD136, the TP-146 drift eliminator uses the 3-pass system to air efficiently out of the drift eliminator while restricting the drift loss to less than 0.002% of circulating water.

Features and Advantages

- The outgoing air is first guided on to the surface of the drift eliminators. This drift laden air then traverses the upward path of the drift eliminator. At the point of the first direction change DrifEl146 introduces a small water entrapment groove. A majority of water droplets are trapped at this notch and channel back into the system.

- Unlike other drift eliminators, where large water entrapment areas lead to increase in pressure drop, the path to air velocity remains sinusoidal, thereby introducing little to no additional pressure drop at this point.

- The air with the remaining drift droplets undergo another direction change and encounter the surface of the adjacent blade. The system continues to work on the principle of inertial separation. At the exit of the drift eliminator, the air undergoes a third direction change while the water droplets encounter a second notch, which entraps a majority of the drift droplets and brings them back into the system.

Technical Specifications

| Characteristics | DrifEl146 |

|---|---|

| Material | Rigid PVC |

| Type Of Structure | Double wall |

| Maximum Face Velocity | 5.0 m/sec |

| Module Length | Up to 3500 mm |

| Module Depth | 146 mm |

| Pitch | 56.5 mm / 66 mm |

| Recommended spacing between supports | 2000 mm |

| Max Recommended Supporting Span | 1830 mm |

| Directional changes for air flow | 3 |

| Average Weight | 8.15 kg/m2 / 6.6 kgs/m2 |

| Maximum Continuous Temperature (deg Celsius) | < 0.002% / 0.05% of circulating water |

| Maximum Continuous Temperature (deg Celsius) | 55°C |